A motorcycle Capacitor Discharge Ignition unit (or CDI or ignitor for short), is a compact electronic unit that controls when and how the spark plug fires which is essential for igniting the fuel-air mixture in the engine.

Note – Before motorbikes started using CDI’s, they used ‘points’ which were mechanical contact breakers used to control the timing of the spark that ignites the fuel/air mixture in the engine.

Points were commonly used in bikes up till the 1980’s when manufacturers started to use CDI’s on bikes.

The main function of the CDI is to provide a precisely timed, high-voltage spark to the spark plug, which then ignites the compressed fuel-air mixture in the engine’s combustion chamber.

This ignition process is what drives the engine.

CDI units from a Kawasaki ER5 (top image) and a 1995 Triumph Trophy 900 (bottom image)

What a CDI does…

- Stores and releases energy. The CDI charges a capacitor and then rapidly discharges it to the ignition coil, creating a high-voltage spark.

- Controls ignition timing. CDI’s determin the precise moment to fire the spark plug.

- Improves high-speed performance. CDI systems are good for engines that run at high RPMs because they deliver quick, powerful sparks.

How the CDI works (basic explanation, in reality they are much more complicated!)…

- Energy storage: The CDI unit contains a capacitor that stores electrical energy. This energy is typically supplied by the motorcycle’s stator (part of the engine’s flywheel that generates electricity).

- Timing signal: A trigger coil (often called a ‘pickup coil’) senses the position of the crankshaft as it rotates. This sends a timing signal to the CDI unit.

- Discharge: When the CDI unit receives the timing signal from the pickup coil, it rapidly discharges the stored electrical energy from the capacitor to the ignition coil.

- Voltage transformation: The ignition coil acts as a pulse transformer, converting the relatively low voltage from the CDI unit into a very high voltage (thousands of volts).

- Spark Generation: This high voltage is then sent to the spark plug, creating a powerful spark that ignites the fuel-air mixture.

Combined CDI and coil unit from a Piaggio Zip 50 scooter

CDI’s are often a black, rectangular box located somewhere under the seat (they can often be seen under the seat or on the side of the rear subframe).

Kawasaki GPZ500S CDI unit.

As with most motorcycle electrical parts, CDI’s can fail with age and/or use.

Some symptoms of a failing CDI are:

- Difficulty starting or the bike not starting

- Weak or no spark at the spark plug

- Engine power loss

- Unstable engine idling

- Engine cutting out/stalling

- Engine misfiring

- Overheating of the CDI unit

CDI’s from a 2002 Yamaha R1 and an XJ600S Diversion

Benefits of using a CDI ignition system…

- Precise ignition timing. The CDI unit ensures that the spark occurs at exactly the right moment in relation to the piston’s position.

- High spark voltage. CDI systems deliver a strong, fast spark, which is beneficial for high revving engines.

- Reliability and low maintenance. Compared to older ‘points’ ignition systems, CDI units have no moving parts, making them more durable and requiring less maintenance.

- Adaptability. Modern CDI units can incorporate features like rev limiters and even programmable ignition mapping to fine-tune engine performance.

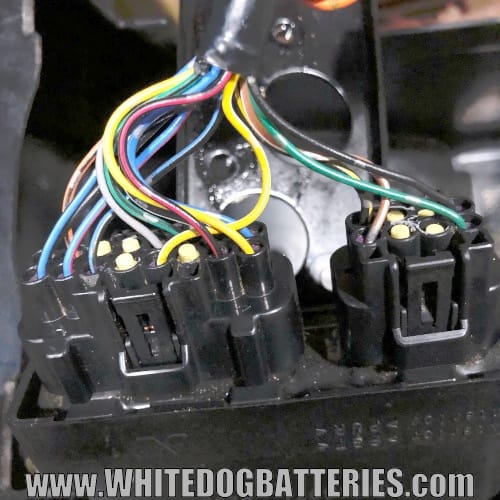

ZRX1200 CDI (top image) and the wiring loom connector block connected to a Kawasaki CDI

Disclaimers:

The information provided on this page is ‘to the best of our knowledge’ and should not be taken as 100% accurate!!

To keep this page as a free resource for people to use, there are affiliate links (mainly Amazon) throughout the article. These affiliate links help maintain the cost of running this blog (basically, if you visit Amazon through one of the links and buy something, we make a few pence!).

Leave a Reply